Quick Details

Condition: New

Voltage: AC380V/50HZ

Rated Power: 4.5KW

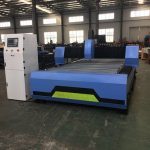

Dimension(L*W*H): 2100mm*3300mm*1500mm

Weight: 1500KG

Certification: CE

Warranty: 1year

After-sales Service Provided: Engineers available to service machinery overseas

working area: 1500mm*3000mm*200mm

Plasma power: 60A 100A 160A 200A

Transmission system: Cylindrical Linear guide Rack driving

Motor: Stepper motor

Control system: Ncstudio/DSP/START

Sensor THC function: Available

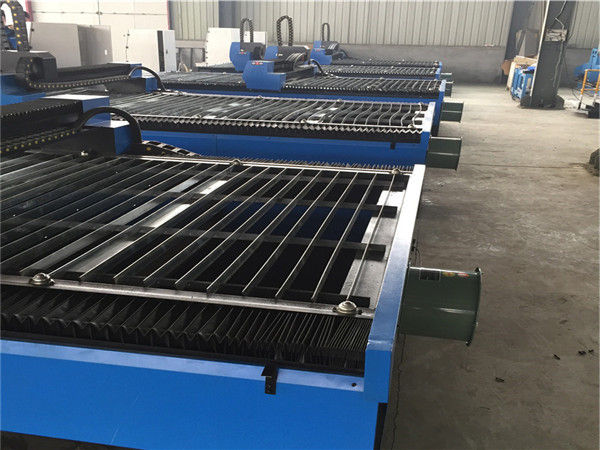

working table: blade table with steel welding

PRODUCT FEATURES

1 .The machine is all welded as seamless steel structure. Steady structure and long life time

2. High configuration, high cutting speed and precision.

3.Auto ARC starting. Steady performance.

4.Control system: DSP handset control, with USB interface.

5. File format: G-code

7. Suitable Software: ARTCUT, Type3, ArtCAM. Beihang Haier.

China plasma pipe cutting machine , high precision plasma cutter , high precision cnc plasma cutter

PRODUCT PARAMETER

| JCUT MODEL | 1530 |

| Working Area (X*Y*Z) | 1500mm*3000mm*200mm |

| Processing accuracy | 0.1mm |

| Repositioning accuracy | 0.01mm |

| Spindle | 60A 100A 160A 200A |

| Spindle rotating speed | 17000mm/min |

| Max Moving Speed | 20m/min |

| Working speed | 10m/min |

| Guideway | Cylindrical Linear rail |

| Driving mode | Rack driving |

| Voltage | AC380V/50HZ |

| Max. Power consumption | 4KW |

| Feeding Height | 200mm |

| Drive motor | Stepper motor |

| Command | G cdoe |

| Controlling system | Ncstudio/DSP/START |

| Compatible Software | ARTCUT, Type3, ArtCAM |

| Certificate | CE |

| Pack dimensions | 2000mm*3200mm81600mm |

| Net weight | 1100KG |

FAQ

1.What is CNC routing?

CNC Routing is a manufacturing process by which a router is controlled by a computer to cut a sheet of material. CNC stands for computer numerical control. Computer conrolled movement of the machine is based on the Cartesian coordinate system (X, Y, Z) allowing for three dimensional shaping.

A CNC router is similar to a plotter which moves a pen across a surface along the X and Y axes to create a drawing. But a CNC router moves a cutting tool across a large table along the X and Y axes as well as up and down along the Z axis. This allows the router to create pocket cuts into the material.

The cutting tool looks like a drill bit, but unlike a drill bit a router is designed to cut from the sides as well as the tip. The router, also referred to as a spindle, is the motor that spins the cutter.

2.How much will CNC routing my design cost?

The cost is determined by the complexity of your design and the material type and thickness you've chosen.

The CNC cuts materials at a range of speeds and as a rule it takes longer to cut thicker materials. As a general rule of thumb, the more lines your design has, the more it will cost to make.