Quick Details

Condition: New

Model Number: LT-1330

Voltage: AC380V±30V,50HZ

Rated Power: 60A power

Dimension(L*W*H): 3150*3200*1200

Weight: 1000KG

Certification: CE

Warranty: 1Year

After-sales Service Provided: Engineers available to service machinery overseas

Product Type: plasma cutting machine cnc

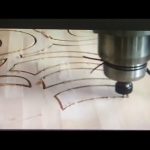

Precision(mm): 0.07

Application: metal cutting

Transmits: gear rack transmits

Power: hypertherm power

Command code: G Code(*.nc,*.mmg,*.u00,etc),*.eng

Drive system: Stepper motors

Working speed(mm/min): 10,000

Largest cutting depth: 5mm

Control system: DSP for plasma

Technical specifications

| Product Type | plasma cutting machine cnc | |

| Model | LT-1330 | optional |

| Working area (X*Y*Z,mm) | 1300*3000*100 | customization is available

|

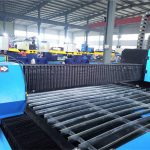

| Machine structure | Channel steel lathe bed serrated table | Square tube lathe bed |

| Working holding | By clamps |

|

| Overall dimension | 3150*3200*1200 | |

| Precision(mm) | 0.07 | |

| Position accuracy(mm) | 0.02 | |

| Repeatability(mm) | 0.02 | |

| Lding speed (mm/min) | 15,000 | |

| Working speed(mm/min) | 10,000 | |

| Document transmission form | USB interface | |

| Working form | Untouched arc striking | |

| Power source | 65A | HUAYUAN100A200A Hypertherm45A/65A/85A

|

| Largest cutting depth | 5mm

| 25mm |

| Drive system | Stepper motors | Servo motors |

| Working voltage | AC380V±30V,50HZ | |

| Command code | G Code(*.nc,*.mmg,*.u00 ,etc),*.eng

| |

| Control system | DSP for plasma | System with THC |

| Compatible software | Window98/XP/7 G code |

Products features

1.steel structure lathe bed is capable of loading heavy metal sheet of large size.

2.Incline design under table surface makes finished parts and scrap slide down to both

side along,convenient ans safe for operator.

3.DSP hand-held control system dedicated for plasma machine,supports file reading from

Udisk or downloading from computer,providing high independence and great convenience

during operation.

4.Racks and gears as transmission raise moving speed so that large area cutting can be

done in short time.

5.High sensitivity THC(Torch Height Controller) is optional for auto adjustment to cutting

distance and cutting precision.

Industrial applicatonis

Widely used in advertising signs, sheet metal structures, high and low voltage electrical cabinet making, textile machinery parts,kitchen utensils, automobile, machinery, elevators, electrical parts, spring, metro parts and other metal parts processing industry.

Services

1.We test equipment at least 3-5 days to ensure our users to receive perfect machines.

2. We guarantee that every part of machine is totally new and clean before delivery.

3. We supply 7*24 after sale service from our Service Department.

4.18 months guarantee for our machines except HSD spindle with 6 months.

5. 24 hours technical support by email,fax or calling.

6. free training in our factory.Also we can dispatch our technician to customers place if customer agree to air ticket,food and hotel.