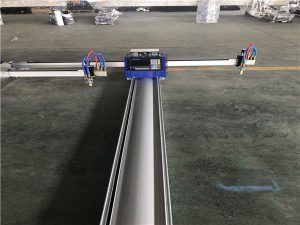

The portable cnc plasma / flame cutting machine is modern cutting equipment with digital program control. In addition to automated cutting, it has high cutting precision, high material utilization and high production efficiency. Along with the mechanical electronic technology and computer technology progress, the CNC cutting machine with its good man-machine dialogue operation interface, powerful auxiliary support function and relative low equipment investment, is being valued by more and more enterprises and more widely used in the production.

It can be widely used in automobile, shipbuilding, petrochemical, boiler and pressure vessel, engineering machinery, light industrial machinery and other industries. Suitable for cutting metal sheets, such as the carbon steel (flame cutting), stainless steel, aluminum, copper (plasma). It particularly applies to a single piece with abnormity surface and the mass production.

(1) Tailored track acquires high-intensity, high-speed and high-precision features.

(2) Human computer interface design makes the machine easy to learn and operate, and have complete functions.

(3) Equipped with functions of portable CNC cutting and can cut carbon steel, stainless steel and non-ferrous metal plate.

(4) Enable the conversion of the CAD into the program file which can be transmitted to the main machine by USB to cut plate into any shape.

(5) With two cutting modes: Flame Cutting & Plasma Cutting.

(6) Chinese, English, French, and Portuguese are ready to use.

(7) Can automatically memorize and restore when power is off.

(8) Plasma THC ( torch height control) device function: By automatically adjust the height of the torches

according to the feedback of the plate height changes, THC can keep good effect of cutting meanwhile,

protect the torch form damage and prolong life span of the nozzles.

(9) With status indication device.

(10) With positioning functions of protection cover, proximity switch and dual-speed.

(11) Compatibility of the domestic plasma and foreign-brand plasma.