Basic Info

Model NO.: SM-D1325

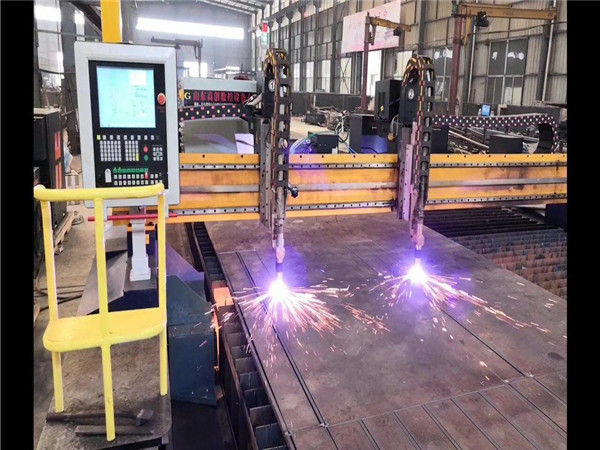

Name: Plasma Cutting Machine

Condition: New

Control System: Starfire or Start

Rails Transmit: Taiwan Hiwin or Abba

Cutting Thickness: 0-50mm

Voltage: 220V for Machine, 380V for Plasma Power

Cutting Speed: 0--8000mm/Min

Machine Type: Portable Type

Min Line Width: 0.1nm

Warranty: 12 Months

Transport Package: Standard Export Plywood Case

Specification: 1500x3000mm

Parameter of the machine

| Model | 1325 1530 2030 (cnc plasma cutting machine) |

| Working area | 1300x2500mm or 1500x3000mm or 2000x3000mm |

| working table | serrated table(sawtooth) |

| Machine Structure | Channel steel lathe bed/heavy duty |

| Rails | Taiwan Hiwin Square rails (ABBA option) |

| Motor | Stepper motor and driver (Servo option) |

| with air compressor | To cool the cutting head, blow away the slag |

| Cutting speed | 15-20m/min |

| Cutting thickness | Depend on current of plasma power source |

| Power supply | Huayuan Power (USA Hypertherm for option) 63A 100A160A 200A |

| Control system | STARFIRE or START |

| Software | Fastcam /Artcam/Type 3 |

| Steel blade saw tooth mesa | Ray plug drives 860 |

| Working mode | Non-contact arc |

| Automatic striking the arc | stable performance, striking the are success rate above 99%. |

| Repeat positioning accuracy | ±0.05mm |

| Process precision | ±0.3mm |

| File transfer mode | USB interface |

| Input voltage | 3 phase 380V for power source, 220V for machine |

| Packing | international standard plywood case packing. |

| Machine size | 3520x2320x1340mm (as 1325) |

Advantages

1 Gantry and box type welded structure, annealed, long service life, steady and durable under heavy load and high duty cycle condition.

2 Gap less gearing transmit, stable and smooth running in high speed, so that we can achieve excellent cutting quality.

3 Integrated auto-ignition with automatic height controller, keep the proper height between cutting torch and work piece, so that we can achieve the best cutting quality.

4 Able to cut work piece with several torches at the same time, can improve cutting efficiency

5 Low use and maintenance cost, dispensing special maintenance, friendly operator interface, easy to learn

6 Reliable, safe CNC system, automatic programming, optimization nesting and piercing path, so that we can save steel effectively

After service

1.1 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed

free of charge if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an agency price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

7.Our staff can be sent to your company to install or adjust if necessary.