Quick Details

Condition: New

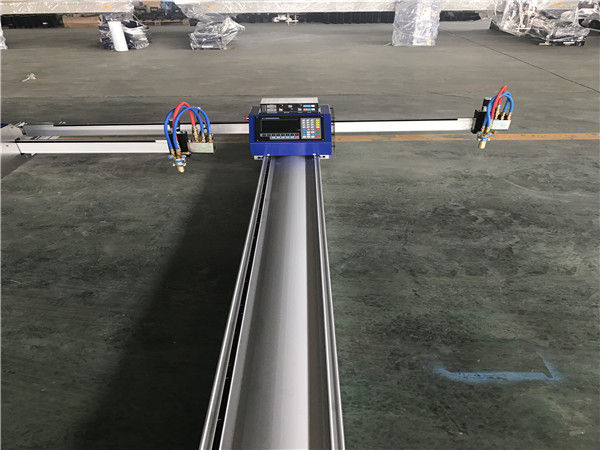

Model Number: used plasma cutting tables for sale

Voltage: 220V/380V/440V

Rated Power: 15KW

Dimension(L*W*H): 3250x2200x1900mm

Weight: 2 TONS

Certification: CE & ISO

Warranty: 2 YEARS

After-sales Service Provided: Engineers available to service machinery overseas

Name: used plasma cutting tables for sale

Company: Factory of CNC Plasma Cutting Machine

Ball screw: Hiwin Square rail from Taiwan

Main Features

- Adopting Sweden ESAB, Japan KOIKE beam, square tube structure through stress-relief and surface oxidation treatment, with high rigidity, high strength, corrosion resistance and guaranteed operation accuracy.

- Cutting torch lifter use towing chain type cable trailer to ensure that the air-pipes, wires be in good protection;

- Cross-beam lifter use one main and multi servo movement method in horizontal direction, up to 6 lifers can be installed on, that is,6 cutting torches, each lifter equipped with a cutting torch and a lifting mechanism;

- In longitudinal direction, using bilateral drive method;

- Longitudinal configuration is equipped with high-precision rack, dedicated heavy-duty railroad rail ( NO.40 rail ), running reliably and accurately, and working surface use finishing grinding technology to ensure the smooth operation and accuracy of the machine.

Standard Configuration

- Shanghai Fangling F2300 CNC system

- X,Y-axes use linear guide rail, Z-axis use ball screw

- HIWIN ball screw and polished rod with accuracy of 0.05mm

- Fixed type large-scale operation system

- Adopting FASTCAM/SMARTCUT CNC cutting software

- Adopting Japan Panasonic P80 cutting head

- X-axis driven by double motors, Y-axis driven by single motor

- France Schneider electrics

- Safety standard(2006/42/EC)

F2300 CNC system

- Up to 45 commonly used graphic library

- Graphic scaling, rotation, mirroring

- Graphic matrix, interleaved, and repetitive

- According to the thickness of the steel plate, it can automatically limit the speed in the corner, effectively prevent over-burning

- Conversion between Metric system and British system

- Graphical steel plate correction

- Coordinate system is customizable

- Customizable IO

- System and parameter backup, online upgrade

- All Chinese / foreign language ( English, Japanese, Russian, French, other custom language ) operation menu, One keyboard toggle

- Line and number are selectable

- Support edge cutting, offset cutting

- With power-off, breakpoint protection memory function

- Dynamic / static fabricating graphics display, graphics zoom in / zoom out, dynamically tracking cutting point under zoom-in status

- Support Wentai, TYPEIII , PM2000 and other special nesting software

- File storage: electronic storage disk, 1G

- User program space: 1G

- Control accuracy: ± 0.001mm

Arc-Voltage Regulator

- HP1201 portable arc-voltage regulator, designed for portable CNC cutting machine, light gantry CNC cutting machine.

- Can be embedded into the cabinet panel, good integration, simple wiring

- New brand design, use SMT ( Surface Mount Technology ) and the latest chip design

- Comprehensively enhance the reliability and anti-interference ability, adding a variety of protection circuit

- Liquid crystal display, real-time display status and parameters, simple and intuitive

- Built-in “isolated voltage plate”, can match with the 1: 1 or 50: 1 arc-voltage input

- Intelligent arc voltage, control accuracy, manual speed, automatic sensitivity and other adjustable parameters

- All-in-one console that can be directly embedded into cutting machine, full-featured, compact body,

- High precision voltage collection, PWM control DC motor, smooth operation, high sensitivity

Flame Cutting Gun

- The whole machine is manufactured by high-quality forged steel

- Adopting equal pressure structure

- The outside diameter of the casing tube is 30mm and 32mm

- Five different lengths of casing tube: 180mm, 250mm, 370mm, 450mm

- The rack can be installed in four different positions ( apart 90 °each position )

- Applicable to the equal-pressure cutting tip with 30-degree conical surface