Product Details

Model Number: CNC

Certification: CE

Place of Origin: WUXI

Minimum Order Quantity: 1

Price: Negotiation

Payment Terms: T/T

Supply Ability: 50 sets/month

Delivery Time: 20 days

Packaging Details: Bubble

Gantry Distance: 4000 mm

Rail Length: 15000 mm

Cutting Speed: 0-6000 mm/min

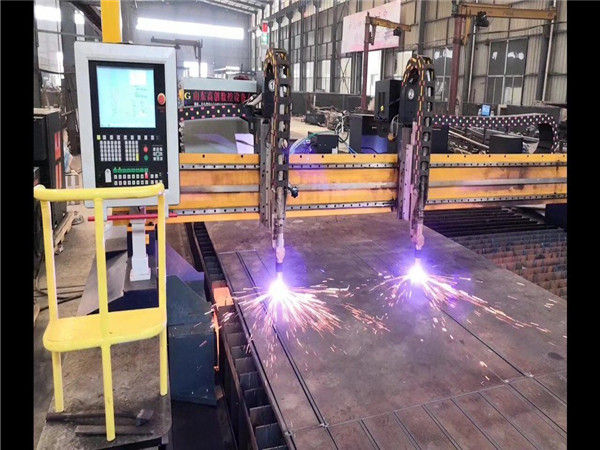

Cutting Torch: Plasma

Quick Detail

1. Voltage : 380V 50 / 60 Hz 3P or as customer's requirment reset.

2. Cutting Way : One plasma cutting gun with one flame welding gun together.

3. Customer can choose the cutting torches quantity according the requirment.

4. Delivery time 20 days

5. One year quality warranty

Description

1.The horizontal guide track adopts a straight line track with high precision and smooth running.The vertical guide track adopts heavy rail.The surface has high precision and wear-ability via grinding post processing.

2.The machine body is gantry type structure:the crossbeam is treated by whole annealing to eliminate stress

3.The programming and jacking software may be equipped with FastCAM, InteGNPS etc. or the needs od users.

4.The travel reducer adopts German high precision planet gear reducer.

5.The digital control system may be equipped with the international famous brands such as USA Hypertherm,Spanish Fagor,or Beijing Startetc.According to the requirements of user.

Specifications

| Rail Span (mm) | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| Effective Cutting Width (mm) | 2300 | 3200 | 4200 | 5200 | 6200 | 7100 |

| Drive Way | Single Drive | Double Drive | ||||

| Rail Length (mm) | □ Standard 15000 mm □ Your requirment | |||||

| Torch Quantity | □ 2 CNC and 9 Strip touches □ Your requirment | |||||

| Cutting Thickness (mm) | □ Flame 6-350 mm □ Plasma According to material | |||||

| Travel Speed (mm/min) | Max 12000 mm/min | |||||

| Cutting Speed (mm/min) | Max 6000 mm/min(Set upon cutting material) | |||||

| Option: | If you have your ideas on the Control System and Cutting Source, then just let us know. | |||||

Competitive Advantage

1. CNC system memory capacity, more than 10000 program files;

2. Supports suspending, forward, backward and speed control;

3. Memory function of power failure;

4. USB interface to transfer the U disk files.

5. FASTCAM Nesting software,programming any complex shapes of plane parts;

6. Built-in graphic database of CNC system,programming easier, efficient operation;