Quick Details

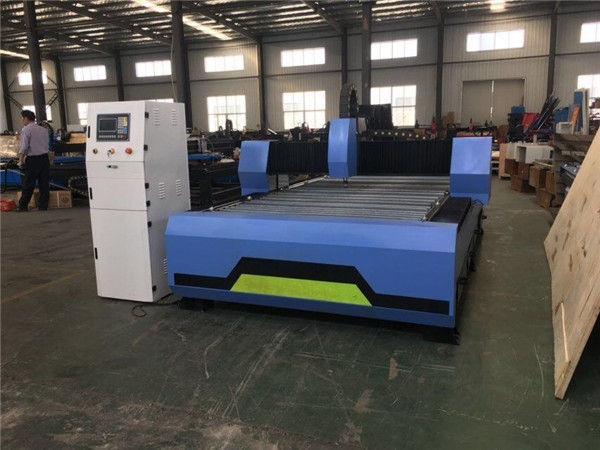

Condition: New

Voltage: 220

Rated Power: 1000W

Dimension(L*W*H): 3305MM*780MM*2110

Weight: 600KG

Certification: ccc

Warranty: 1year

After-sales Service Provided: Engineers available to service machinery overseas

brand: nakeen

cutting mode: plasma

cutting thickness: 0.1-16mm

cnc or not: yes

cutting area: 1300*2500

file information: USB

MOQ: 1SET

PACKING: PLYWOOD CASE

CUTTING material: metal .alloy metal .aluminum

height control: arc voltage height control and electric

Product advantage

1.Bilateral drive,stable operation

2.High precision, good effect

3. Arc voltage height (THC)

4.Can be installed a water spraying device, reduce the thermal deformation

5.Can cut carbon steel, stainless steel, copper, aluminum and other non-ferrous metals

6. Simple operation & maintenance and so on.

Features and advantages

1. Compare with the plasma cutting, it has the high precision cutting for different kinds of metal materials, like cutting stainless steel, carbon steel, alloy steel, spring steel, aluminum, copper, silver, titanium and other metal materials below 6 mm.

2. Compare with the NC, which can cut any complicated process and shape.No noise and no need to open any moulds at all.

3. Compare with linear cutting, which has much faster speed,100 times higher than it.

4. Double lead screw to drive, Small heat affected zone, good dimension stability. Flat and handsome laser-slotted, without later process

5. High performance/price ratio: the price is only 1/8 of the similar CO2 laser cutting machine and 2/5 of the equivalent NC Punch

6. Low use cost: only USD2 per hour which is 1/8-1/10 of the similar CO2 laser cutting machine (USD22-USD35 per hour)

7. Low follow-up maintenance cost: only 1/10-1/15 of the similar CO2 laser cutting machine and 1/3-1/4 the equivalent NC Punch

8. Steady performance: as a mature laser apparatus, the YAG laser cutting machine is suitable for most metal manufacturing and processing industry.

Technical parameters

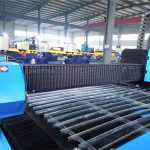

| 1 | Cutting shape | any shapes |

| 2 | LCD Display Dimension | 7.0Inches |

| 3 | Effective Cutting Width (X axis) | 1300mm |

| 4 | Effective Cutting Length (Y axis) | 2500mm |

| 5 | Cross Beam Length | 1800mm |

| 6 | Longitudinal Rail Length | 3000mm |

| 7 | Cutting Speed | 0-8000mm per minute |

| 8 | Plasma Cutting Thickness | 2--20mm ( Depends on plasma power source capacity) |

| 9 | lifting body | 1set |

| 10 | Drive Mode | bilateral drive |

| 11 | Cutting Mode | plasma |

| 12 | Ignition device | Auto ignition device |

| 13 | Height regulating device | Arc voltage height |

| 14 | File transmission | USB transmission |

| 15 | Nesting software | Fastcam standard |

| 16 | File transmission | USB |

| 17 | LCD Display Dimension | 7" colour |

| 18 | Plasma Power Source | Hypertherm PowerMAX65/85/1650 or other |

| 19 | Plasma Air | Only pressed Air |

| 20 | Plasma Air Pressure | Max. 0.8Mpa |

| 21 | Cutting precision | ±0.5mm National standard JB/T10045.3-99 |

| 22 | Control accuracy | ±0.01mm |

| 23 | Power Supply Voltage/Frequency | 220V 50HZ |

| 24 | Rated Power Supply | 1000W |

| 25 | Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

Control system and software introduction

This control system is composed by the industrial PC, center control card, controller display of power supply, professional control software. The PC is installed into the control box, the center control card receive the orders from the software and execute it. Through the controller display of power supply, we light the Xe lamps, adjust the cutting parameters like current, frequency, pluse width accroding to different materials and plate thickness. And through the control software, we imput the cutting file, add the lead line, give kerf compensation, fix cutting position and so on.